Wear Rings/ Bearing Rings/ Bearing Strip

Function of a Bearing Ring

The function of the Bearing or wear ring is to guide the piston or rod of a hydraulic cylinder and help keep the piston centered allowing for even wear and pressure distribution on the seals, at the same time helping to withstand arising side loads. And preventing any metal-to-metal contact which would damage and score the surfaces eventually causeing seal damage resulting in leakage and component failier..

Popular wear ring materials include Glass filled nylon,Acital, Bronze reinforced PTFE, Glass reinforced PTF, and Phenolic.

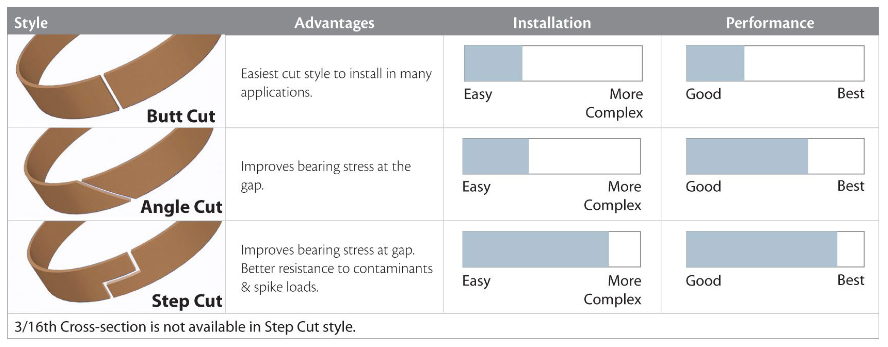

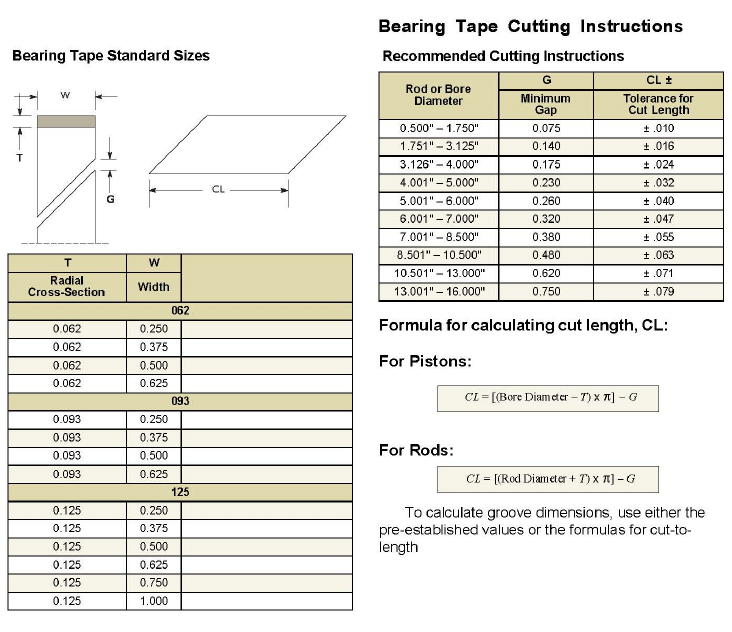

Wear rings are used in both piston and rod applications being supplied in moulded machined or available in coils from which bearing rings can be cut there are 3 cutting styles, butt cut, angle cut, and step cut styles.

Materials Temp. Range

- Carbon Graphite filled PTFE -260°C to 260°C

- Glass filled Nylon -240°C to 121°C

- Glass filled PTFE -260°C to 260°C

- Bronze filled PTFE -260°C to 260°C

- Phenolic -60°C to 130°C

As an addition our state of the art cad machining capabilities produce supply and design a full range of existing and R & D prototypes along with the ability to retrofit existing modular and non modular designs from samples or drawings