Back up / Antiextrusion rings

Back-up rings are washer-like devices that are used to prevent a seal from extruding through any gaps while under pressure. These seals are installed in the downstream side of the gland. Back-up rings are not seals themselves, but are usually used in conjunction with O-rings in high-pressure applications (over 1500 psi) for support or as spacers

SF

SG

Applications

Typical applications include

• Hydraulic cylinders

• High-pressure hydraulic systems,

• High-pressure valves.

In some applications such as doublle acting pistons it is best to use two back-up rings; one above the o-ring and one below, to provide maximum support.

Configurations

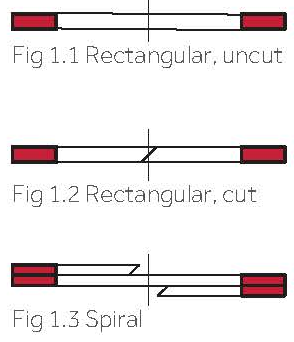

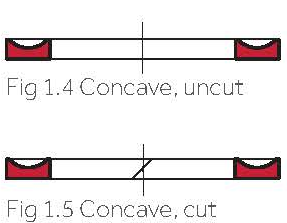

Back-up rings are available in two distinct face design configurations – a flat, washer style, and contoured. The simplest form has two flat, parallel surfaces, much like a washer.

In contoured back-up rings, one face is straight and the opposite face is curved or contoured. The contoured face is the one that comes in contact with the o-ring, providing better grip and support.

Back-up rings may be of solid or spiral construction.

Spiral Backup Rings

Spiral back-up rings are of overlapping, coiled construction. As the o-ring exerts pressure upon them, the overlapping rings provide a number of contact levels against the shaft providing extra support.

Specifications

When selecting between the numerous types of back-up rings available, the three most important specifications to be aware of are

• Inner Dimension of the Ring, or the outer dimension of the shaft on which the back-up rings will be applied;

• Radial Cross Section of the seal;

• Ring Thickness, or the axial width of the cross section of the ring, calculated as (ring O.D. – ring I.D.)/2.

Materials

Back-up rings are can be supplied in numerous compounds and material compounds Ptfe,Nbr,Viton, Polyurethane and Leather for older applications even metallic or natural materials can be supplied, each of which have specific advantages and disadvantages depending upon the application in which the back-up rings will be used.

In some cases, seal manufacturers use their own proprietary materials in the manufacture of back-up rings. When in doubt, it is best to check with our technical or sales team as to which material would be best for the application at hand.

Standards

BS 5106 – Specification for dimensions of spiral anti-extrusion back-up rings and their housings

DIN ISO 3601-4 – Fluid power systems – o-rings – part 4

JIS B 2401-4 – o-rings – part 4: anti-extrusion rings (back up rings)

SAE AS5860 – retainers, (back-up rings), hydraulic and pneumatic, polytetrafluoroethylene resin, single turn, static gland